3S production line for rice processing quality beyond your imagination

Release Date: 2022-02-28 Source: Views: 204

Gongan County is located in the central and southern part of Hubei Province, facing Jingzhou City across the river。Rich local water resources and good land conditions make it a famous national town of fish and rice, Hubei Kaidi Grain Industrial Co., Ltd. is located here, it has advanced rice processing production line, daily output of up to 200 tons, is a high-quality grain production enterprises。At the same time, the rice processing technology is boldly updated on the production line upgrade, and it is at the forefront of the development of the industry。This issue of "Into the cloud vision of quality selection" lets us understand the innovation of Hubei Kaidi Grain Industrial Co., Ltd. in rice processing technology。

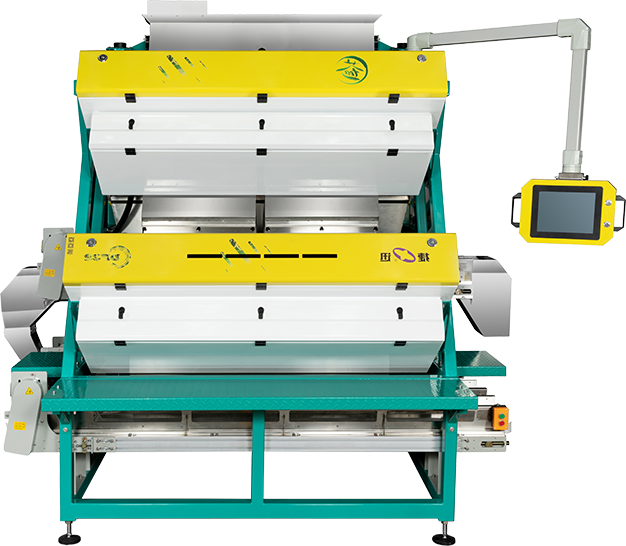

SF cloud quality sorting machine has shown great power in the new sorting method of grain roughness

SF grain rough cloud quality sorting machine has made great progress in the process of back hulling material selection, brown rice quality selection, husking material selection and so on. This time, Kaidi Grain Industrial Company applied SF cloud quality sorting machine to introduce a new process: gravity grain rough sieve back to the screen material and rice removing machine material into SF cloud quality sorting machine for sorting。After the SF cloud sorting machine quality, the quality of the rice feeder brown rice has been improved, more importantly, because the gravity grain sieve back to the screen material with the brown rice finished material into the SF cloud sorting machine, so that the yield of brown rice has also increased a lot。According to the calculation of Liu Gang, general manager of Kaidi Grain Industry Company, in the case that the raw material content of rice into the SF cloud quality sorting machine is constantly changing in the range of 5-30%, the brown rice into the rice machine has increased by more than 20%。Too much brown rice is one of the main reasons for the crushing of brown rice in the husking section. The more rice is broken, the more value of rice processing enterprises will be lost。In order to increase the value that the enterprise can obtain, Kaidi Grain Industrial Company chose to reduce as much as possible the flow rate of husking under the gravity grain sieve after installing the SF cloud quality sorter, so that more materials directly into the SF cloud quality sorter, thus reducing the amount of husking under the gravity grain sieve, and thus reducing the amount of brown rice contained in the husking material。

The selection of superior value for removing impurities and purifying quality and upgrading grain roughness

In the rice milling section of rice processing, due to the interference of external factors, it is easy to break, and the rice stalk disease block will pollute the rice and oil bran after being rolled in the rice milling machine, which is easy to cause the product can not sell at a good price。Liu Gang, general manager of Kaidi Grain Industry Company, naturally also wanted to solve such a problem, when he understood that SF cloud quality separator can not only separate the grain rough but also select impurities, he added a SF cloud quality separator after the gravity grain rough screen in his own production line。The SF cloud quality sorter also lived up to his trust,Impurities such as rice stalk disease, black rough, stone, plastic, glass, platycodon, cigarette butt, fruit shell, welding slag, braid rope and broken belt were selected,This not only improves the grade of oil bran, but also reduces the content of impurities in oil bran,The risk of aflatoxins and plasticizers has been prevented and controlled。Of course, it also reduces the broken rice rate of the rice milling section。

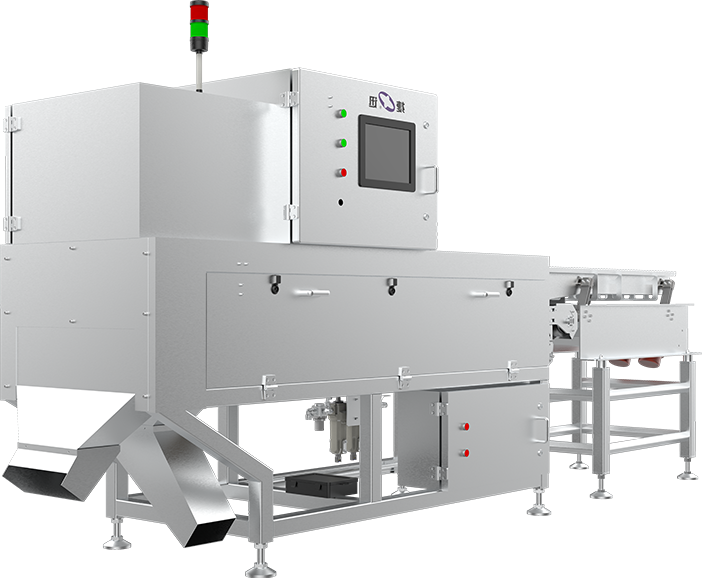

The difficult problem is solved by sorting and grading the whole particle Quality selection 3S technology creation myth

As we all know, the white rice classification for the control of broken rice indicators has been a problem, while the traditional equipment classification of broken rice contains a high rate of integrity, even after processing again is still a large number, so that the loss of rice processing enterprises is actually very large。In addition, the traditional white rice grading equipment replacement or cleaning screen is very cumbersome, troublesome, laborious, time-consuming can not complete the whole classification, not to mention the rice processing is difficult to avoid the variety of mixed processing。Kaidi grain Industrial Company has been using the white rice grading screen to screen the broken rice before the finished product bin before using the SD cloud quality separator, not only the large crushed rice screened out of the whole rice, but also the estimated amount to prevent the product broken rice exceeded the standard, so both sides have brought huge losses to the enterprise。After installing the SD cloud quality sorter in the production line, General manager Liu Gang chose to let the white rice grading screen in front of the warehouse only sift small pieces, and the rest directly into the warehouse。Before the rice packaging, according to the customer's requirements, the SD cloud quality selection machine is used to select a variety of rice containing broken grades, which not only solves the problem of the finished product containing too much broken rice and the large and medium broken rice containing too much whole in one fell fell, but also easily solves the problem of the excessive content of broken rice per bag in the packaging process caused by the automatic classification of white rice in the finished product warehouse。One SF grain rough cloud quality sorting machine in Husking section, one SD crushing and grading cloud quality sorting machine after rice finished products are discharged from the warehouse, and one SC yellow and white cloud quality sorting machine in polishing section。A rice production line with a daily output of 200 tons uses only three cloud quality sorting machines to form a standard quality selection 3S production line, which ensures the quality of rice products and improves themRice production, improve the value of rice utilization while saving the footprint of mechanical equipment。

Science and technology fast, quality choose the future。Quality selection 3S process promotes the transformation and upgrading of new processes and new equipment of grain and oil processing enterprises, enables the improvement of product value of enterprises, and promotes the development of rice processing towards digital intelligence and flexibility。

Gongan County is located in the central and southern part of Hubei Province, facing Jingzhou City across the river。Rich local water resources and good land conditions make it a famous national town of fish and rice, Hubei Kaidi Grain Industrial Co., Ltd. is located here, it has advanced rice processing production line, daily output of up to 200 tons, is a high-quality grain production enterprises。At the same time, the rice processing technology is boldly updated on the production line upgrade, and it is at the forefront of the development of the industry。This issue of "Into the cloud vision of quality selection" lets us understand the innovation of Hubei Kaidi Grain Industrial Co., Ltd. in rice processing technology。

SF cloud quality sorting machine has shown great power in the new sorting method of grain roughness

SF grain rough cloud quality sorting machine has made great progress in the process of back hulling material selection, brown rice quality selection, husking material selection and so on. This time, Kaidi Grain Industrial Company applied SF cloud quality sorting machine to introduce a new process: gravity grain rough sieve back to the screen material and rice removing machine material into SF cloud quality sorting machine for sorting。After the SF cloud sorting machine quality, the quality of the rice feeder brown rice has been improved, more importantly, because the gravity grain sieve back to the screen material with the brown rice finished material into the SF cloud sorting machine, so that the yield of brown rice has also increased a lot。According to the calculation of Liu Gang, general manager of Kaidi Grain Industry Company, in the case that the raw material content of rice into the SF cloud quality sorting machine is constantly changing in the range of 5-30%, the brown rice into the rice machine has increased by more than 20%。Too much brown rice is one of the main reasons for the crushing of brown rice in the husking section. The more rice is broken, the more value of rice processing enterprises will be lost。In order to increase the value that the enterprise can obtain, Kaidi Grain Industrial Company chose to reduce as much as possible the flow rate of husking under the gravity grain sieve after installing the SF cloud quality sorter, so that more materials directly into the SF cloud quality sorter, thus reducing the amount of husking under the gravity grain sieve, and thus reducing the amount of brown rice contained in the husking material。

The selection of superior value for removing impurities and purifying quality and upgrading grain roughness

In the rice milling section of rice processing, due to the interference of external factors, it is easy to break, and the rice stalk disease block will pollute the rice and oil bran after being rolled in the rice milling machine, which is easy to cause the product can not sell at a good price。Liu Gang, general manager of Kaidi Grain Industry Company, naturally also wanted to solve such a problem, when he understood that SF cloud quality separator can not only separate the grain rough but also select impurities, he added a SF cloud quality separator after the gravity grain rough screen in his own production line。The SF cloud quality sorter also lived up to his trust,Impurities such as rice stalk disease, black rough, stone, plastic, glass, platycodon, cigarette butt, fruit shell, welding slag, braid rope and broken belt were selected,This not only improves the grade of oil bran, but also reduces the content of impurities in oil bran,The risk of aflatoxins and plasticizers has been prevented and controlled。Of course, it also reduces the broken rice rate of the rice milling section。

The difficult problem is solved by sorting and grading the whole particle Quality selection 3S technology creation myth

As we all know, the white rice classification for the control of broken rice indicators has been a problem, while the traditional equipment classification of broken rice contains a high rate of integrity, even after processing again is still a large number, so that the loss of rice processing enterprises is actually very large。In addition, the traditional white rice grading equipment replacement or cleaning screen is very cumbersome, troublesome, laborious, time-consuming can not complete the whole classification, not to mention the rice processing is difficult to avoid the variety of mixed processing。Kaidi grain Industrial Company has been using the white rice grading screen to screen the broken rice before the finished product bin before using the SD cloud quality separator, not only the large crushed rice screened out of the whole rice, but also the estimated amount to prevent the product broken rice exceeded the standard, so both sides have brought huge losses to the enterprise。After installing the SD cloud quality sorter in the production line, General manager Liu Gang chose to let the white rice grading screen in front of the warehouse only sift small pieces, and the rest directly into the warehouse。Before the rice packaging, according to the customer's requirements, the SD cloud quality selection machine is used to select a variety of rice containing broken grades, which not only solves the problem of the finished product containing too much broken rice and the large and medium broken rice containing too much whole in one fell fell, but also easily solves the problem of the excessive content of broken rice per bag in the packaging process caused by the automatic classification of white rice in the finished product warehouse。One SF grain rough cloud quality sorting machine in Husking section, one SD crushing and grading cloud quality sorting machine after rice finished products are discharged from the warehouse, and one SC yellow and white cloud quality sorting machine in polishing section。A rice production line with a daily output of 200 tons uses only three cloud quality sorting machines to form a standard quality selection 3S production line, which ensures the quality of rice products and improves themRice production, improve the value of rice utilization while saving the footprint of mechanical equipment。

Science and technology fast, quality choose the future。Quality selection 3S process promotes the transformation and upgrading of new processes and new equipment of grain and oil processing enterprises, enables the improvement of product value of enterprises, and promotes the development of rice processing towards digital intelligence and flexibility。